One of the most frustrating issues in flooring is having a beautiful new hardwood floor installed that doesn’t look like what the customer expected. Problems concerning the appearance of different grades of flooring are among the most numerous complaints that flooring contractors have to deal with.

Because the characteristics of wood species and types of wood flooring vary so much, there are no standard grades for all wood floors. Some wood flooring grades are determined by industry associations, such as the NWFA/National Oak Flooring Manufacturers Association.

Most wood flooring grades deal with the aesthetics of the floor, not the serviceability. All grades will perform equally well; it’s their facial appearances that vary. In this sense, flooring of a higher grade is not necessarily better. It is a matter of personal taste.

Most grading rules also dictate the average length of the boards involved. Higher grades of flooring usually have longer boards, so be prepared for many shorter boards if you order a lower grade of wood flooring.

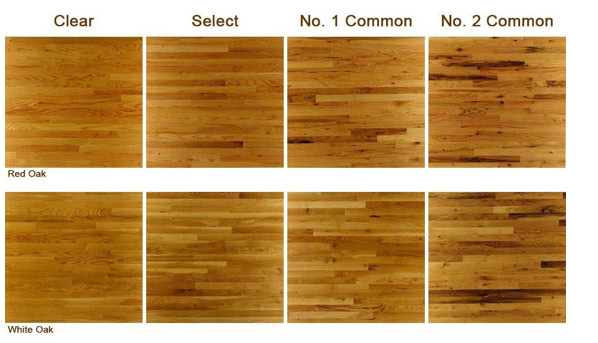

An example of how grades work are the rules for one of the most common wood floors installed; solid, unfinished red or white oak. Under those grading rules, there are four levels of oak flooring; Clear, Select, No. 1 Common and No. 2 Common.

Clear Oak is very uniform in color, with very few small character marks. Its average board length is 3 ¾ feet. Select oak has more color variation and more natural character marks such as small knots. The average board length for Select oak is 3 ¼ feet.

No. 1 Common has a much more varied appearance, with mineral streaks, greater color variation, and more character marks, and average board length is 2 ¾ feet.

No. 2 Common, has a “rustic” appearance, with just about any natural character mark, including large knots and very dark boards.

Wood cut

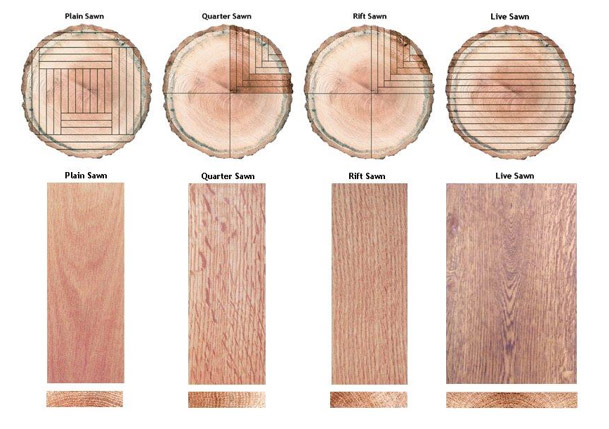

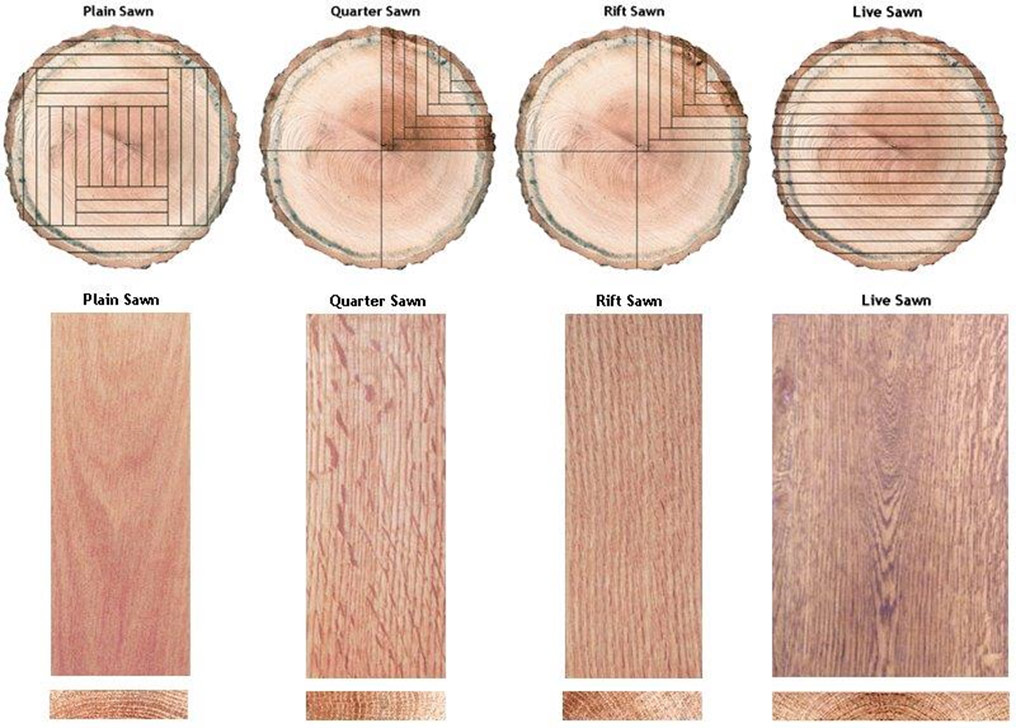

Another factor that can affect the appearance of your hardwood floor is the way the flooring was cut from the log itself.

Quartersawn More expensive than Plainsawn as it is more labor-intensive to produce, featuring greater wear resistance, less tendency to cup and twist, less shrinkage in width, and uniform grain appearance with ray flecks. Ray flecks are decorative figures that appear in flooring cut across the wood’s ray cells, creating a shimmering flake figure in the wood. The straight grain pattern especially lends itself to design.

Rift sawn This cut is similar to Quartersawn, but without the ray flecks. It is also referred to as radial grain.

Live sawn A unique method of sawing a log straight through its diameter, preserving the heart of the log, and all the grain and character variations seen throughout the lumber. Live sawing is a very efficient use of the lumber, and therefore creates less waste product.